Mastering Copper Tube Bending: Techniques, Tools, and Tips for Perfect Curves

-

Quick Links:

- Introduction

- Understanding Copper Tubing

- Tools and Materials Needed

- Bending Techniques

- Step-by-Step Guide to Bending Copper Tubing

- Common Mistakes to Avoid

- Case Studies

- Expert Insights

- FAQs

Introduction

Copper tubing is a versatile material used in various applications, from plumbing to artistic projects. Learning how to bend copper tubing properly can save time, money, and resources. In this extensive guide, we will dive deep into the techniques and tools you need for perfect bends every time.Understanding Copper Tubing

Copper tubing comes in various types, such as Type K, L, and M, each with different wall thicknesses and applications. Before bending, it's essential to understand the characteristics of the copper tubing you are working with.Types of Copper Tubing

- Type K: Thickest walls, used for underground and high-pressure applications.

- Type L: Moderate wall thickness, commonly used in residential plumbing.

- Type M: Thinner walls, suitable for light-duty applications.

Properties of Copper

Copper is known for its malleability, which allows it to be bent without breaking. However, it's essential to work within certain limits to avoid kinks or cracks.Tools and Materials Needed

Before you start bending copper tubing, gather the necessary tools and materials:Essential Tools

- Copper tubing bender

- Pipe cutter

- Deburring tool

- Tape measure

- Marker or scribe

- Safety goggles

Materials

- Copper tubing (select the type based on your project)

- Optional: bending springs and lubricant

Bending Techniques

There are several techniques to bend copper tubing, including:1. Using a Tube Bender

A tube bender is a specialized tool that allows for precise bends without kinking the tubing. Follow the manufacturer's instructions for optimal use.2. Using Bending Springs

Bending springs can be inserted into the tubing to prevent it from collapsing during the bending process.3. Manual Bending

For smaller bends, you can use your hands, but be cautious not to apply too much pressure, which can lead to kinks.Step-by-Step Guide to Bending Copper Tubing

Here’s a detailed process for bending copper tubing successfully:Step 1: Measure and Mark

Use a tape measure to determine the length of tubing required and mark the bending point with a marker.Step 2: Prepare Your Tools

Gather your tools and ensure they are in good condition.Step 3: Insert the Tubing into the Bender

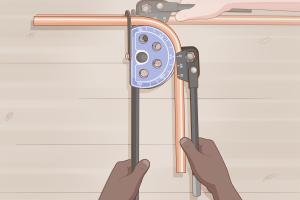

Place the marked tubing into the bender, aligning it with the appropriate mark on the tool.Step 4: Apply Pressure

Slowly and steadily apply pressure to the handle of the bender until you reach the desired angle.Step 5: Check Your Bend

Remove the tubing and inspect the bend for smoothness and accuracy. If necessary, make adjustments.Step 6: Deburr the Edges

Use a deburring tool to smooth the edges of the cut tubing, preventing any injury during handling.Common Mistakes to Avoid

Bending copper tubing can be tricky. Here are some common pitfalls to avoid:- Not measuring accurately can lead to wasted material.

- Using too much force can kink the tubing.

- Failing to deburr can cause injuries or leak points in plumbing applications.

Case Studies

To illustrate the importance of proper copper bending techniques, let’s look at a couple of real-world examples:Case Study 1: Residential Plumbing

A plumber in a suburban home faced issues with kinks in copper tubing installations. By switching to a tube bender and using proper techniques, he reduced waste and improved job efficiency.Case Study 2: Artistic Projects

An artist creating copper sculptures found that using bending springs allowed for more intricate designs without compromising the tubing’s integrity.Expert Insights

We reached out to several plumbing and metalworking professionals to gather their insights on bending copper tubing. Here are some key takeaways: - **Practice makes perfect:** Many professionals recommend practicing on scrap pieces before starting on the actual project. - **Invest in quality tools:** Good quality benders and cutters make a significant difference in the quality of the bends. - **Safety first:** Always wear protective gear, especially when cutting and bending materials.FAQs

1. Can I bend copper tubing without a bender?

Yes, but it requires more skill and may result in kinks. Using bending springs can help if you don't have a bender.2. What is the best type of copper tubing for bending?

Type L is generally preferred for its balance of thickness and flexibility.3. How do I avoid kinks when bending?

Use a bender specifically designed for copper tubing and apply pressure evenly.4. Can I reuse bent copper tubing?

Yes, but ensure the bends are not damaged.5. How do I clean the edges after cutting?

A deburring tool is ideal for cleaning cut edges.6. Is it necessary to use lubricant when bending?

It can help reduce friction, especially for tight bends.7. What is the maximum angle for bending copper tubing?

Generally, a 90-degree bend is acceptable, but tighter bends can risk kinking.8. How do I know if I've bent the tubing correctly?

The bend should be smooth and uniform without any visible kinks.9. What tools are essential for a DIY copper bending project?

A tube bender, pipe cutter, and deburring tool are essential.10. Where can I find copper tubing?

Local hardware stores, plumbing supply companies, and online retailers all carry copper tubing.Random Reads

- How to remove stains from stainless steel

- How to fix a squeaky floor

- How to fix a treadmill

- How to make a bar chart in word

- How to make a bar graph in excel

- How to remove echo from audio

- How to remove fence posts

- How to roll stats dnd 5e

- How to rip music cd to usb

- A complete guide to layer masks in photoshop